Project One.

£1,100 (ex VAT)

Injection Moulded Part.

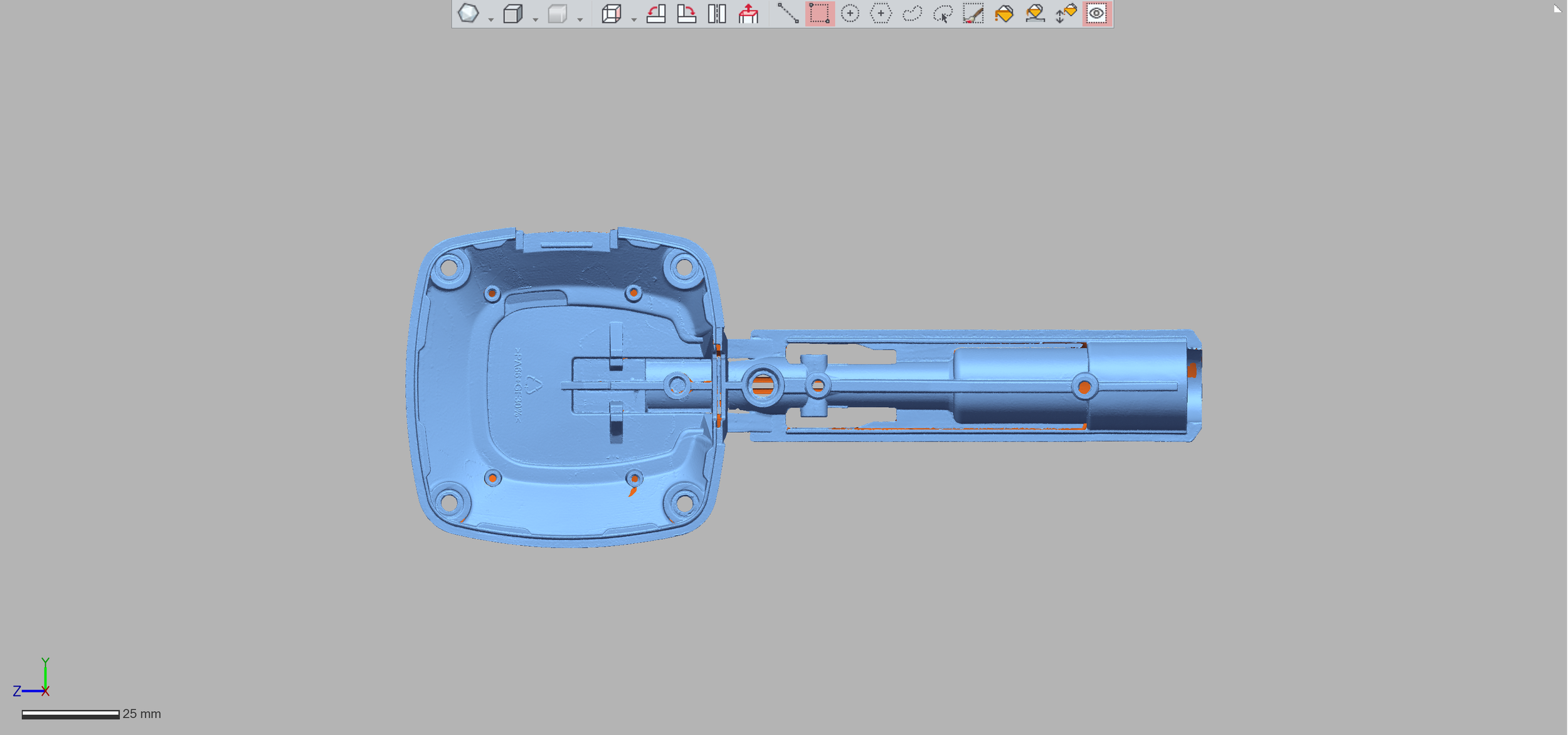

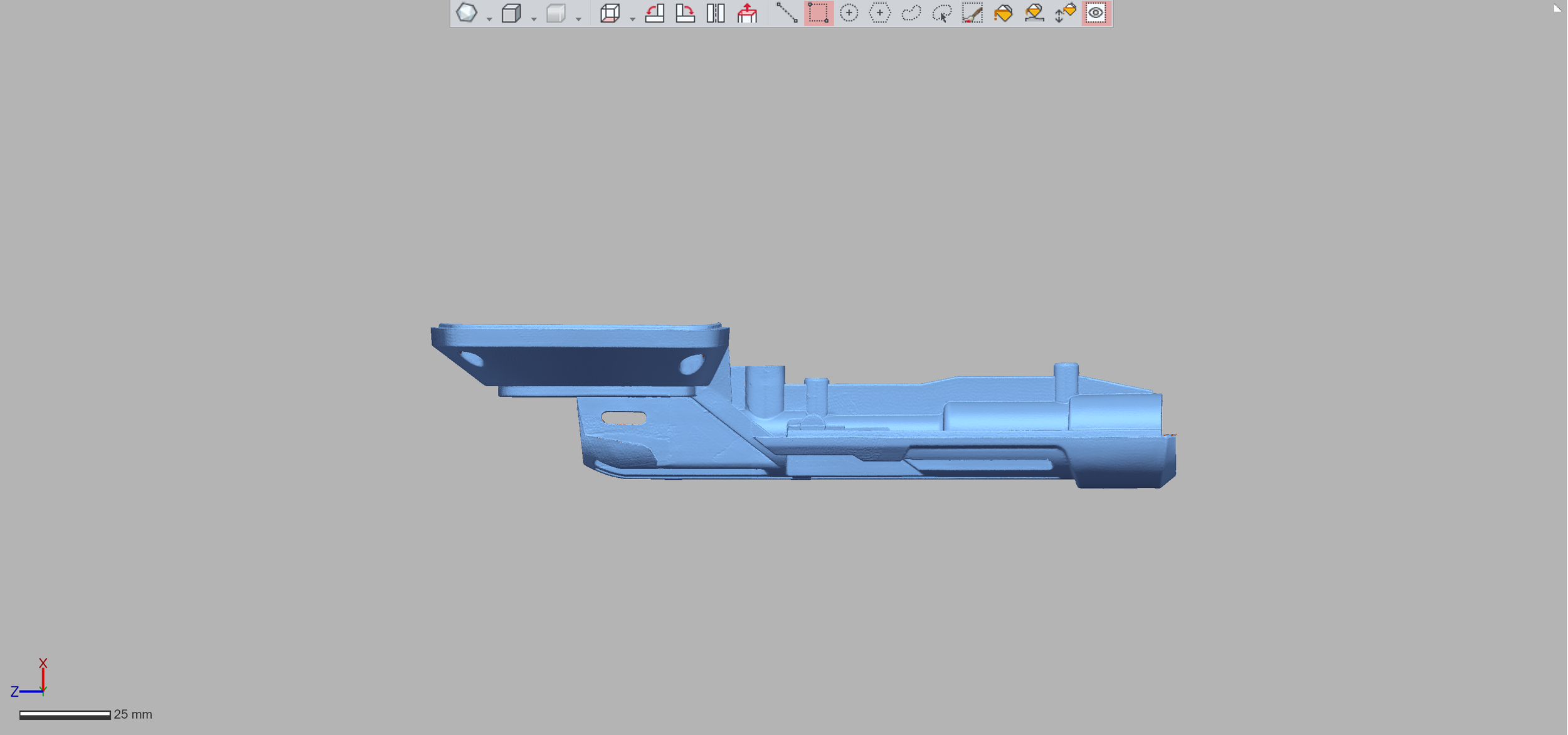

Overview: This injection moulded part had been modified over the years through tooling modifications, but the part's CAD had not been kept in line. We were required to scan the existing part and create an accurate design intent model. We were also required to create a native Solidworks file so the customer could produce in house technical drawings.

-

Scanning the external geometry of this part was relatively straightforward. We just had to ensure we captured data from various angles.

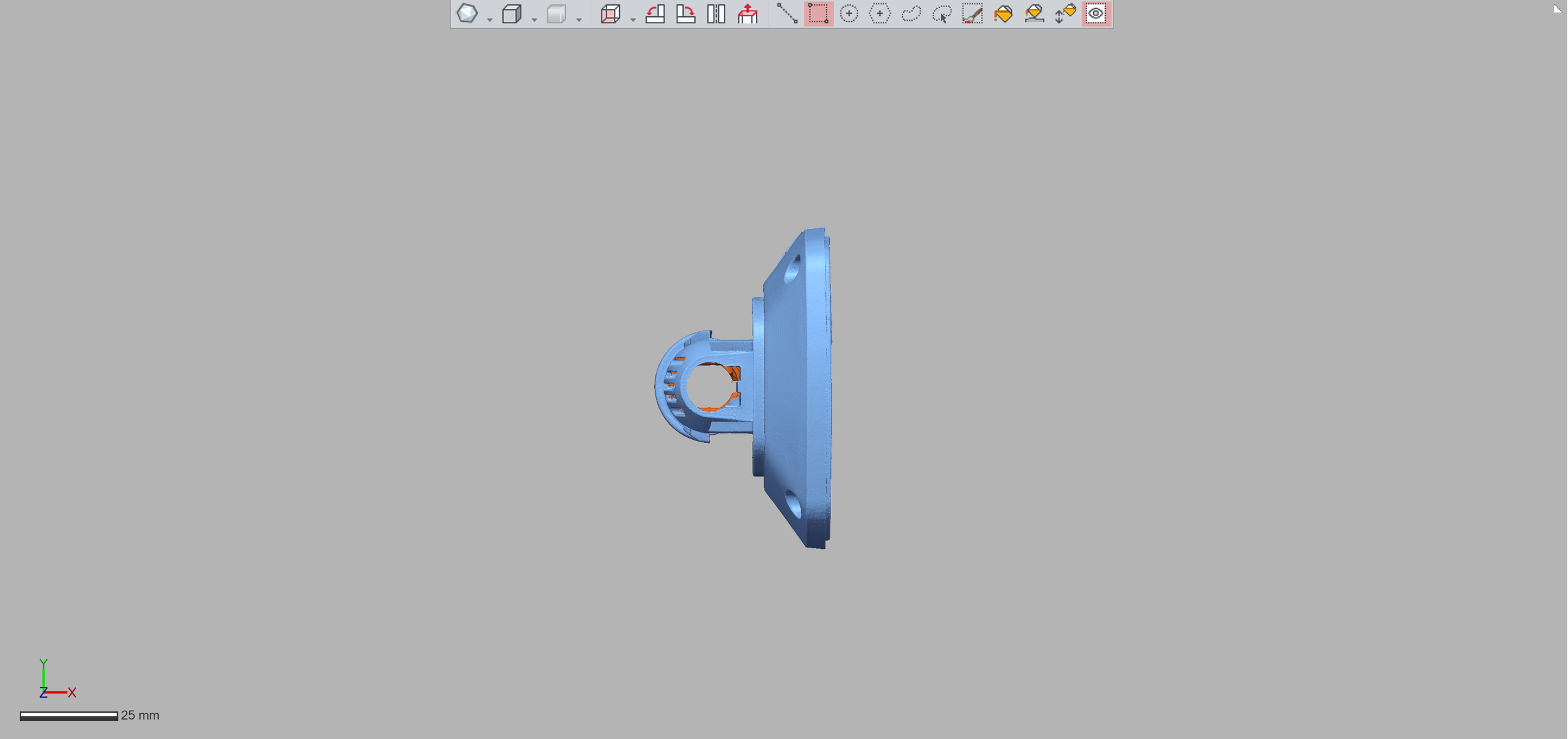

The challenge was scanning the internal geometry of the part. We could have sent this off for CT scanning, but this would have added unnecessary additional costs and time to the project. Instead, we created replica moulds of the internal cavities with silicone moulds. We then scanned these moulds and added them to our scanned model.

-

Again, reverse engineering this product was relatively straightforward. There was no complex surface modelling - just simple sketches, extrudes, revolves etc. However, there were a lot of features to reverse engineer, which took a significant amount of time.

Throughout this project, we constantly considered design for manufacture, looking at draft angles, undercuts, etc., to ensure this product could be manufactured using injection moulding.

-

The final inspection was to compare the CAD model we produced against scan data we captured.

Cost Breakdown.

| Project Two. | ||

| Product Details | Qty | Price |

| Laser Scanning Laser scan existing part. Capture any internal cavities with silicon moulds. |

1 | £150 |

| Create STL File Data processing and alignment |

1 | £150 |

| Reverse Engineer Parametrically reverse engineer to design intent. |

1 | £500 |

| Solidworks Live Transfer Covert the CAD model into a native Solidworks file for additional modifications. |

1 | £300 |

| Total | £1,100 ex VAT | |

Native Solidworks.

We reverse engineer using a specialised CAD package called Geomagic Design X. This CAD software is ideal for reverse engineering as it allows you to reference scan STL data to create your 3D model accurately. Geomagic Design X has another feature called live transfer, which allows you to move your full parametric design tree into other CAD packages such as Solidworks.